Industrial Machinery

- HOME

- Business

- Industrial Machinery

- Shipbuilding fabrication system

- Steel structure fabrication system

- Iron manufacturing equipment

- Transportation equipment

- Portable Heat Exchanger Purification System

- Asphalt Product Mixing & Packing System

- Welding Gantry Robot System

- Press Line

- Package Line

- 6Speed TM Case & CVT Housing Assembly Line

- Hub Carrier Assy Assembly Line

- Γ-ENG Ladder Frame Assembly M/C

- Servonutrunner(2axis)

- Knuckle Bush Pressing machi

- Disc Vision Inspection M/C

- Hub Tap Inspection and location Vision Inspection M/C

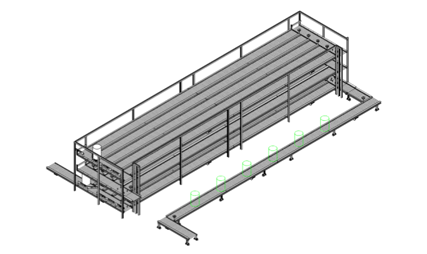

- Automatic packaging device

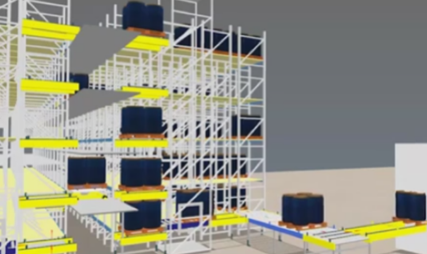

- Drum Storage, Feeding & Filling Auto System

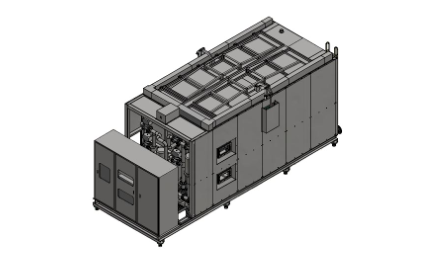

Shipbuilding fabrication system

Plate joining machine

| Dscription | Specification |

|---|---|

| Tack Welding Method | FCAW (Manual Welding) |

| Current Range | Max. 350 A |

| Traveling Speed | Max. 15 m/min |

| Traversing Speed | 17 m/min |

| Plate Pressing Power | 8Ton/Ea x 4Ea x 2Set = 64Ton |

| Slewing Angle | -90°, 0°, +90° |

| X-Y-Z Slide | Z Dir Stroke : 400mm |

| Pulling Magnet | 2.5 Ton x 4Ea = 10Ton (∅315mm) |

Butt welding machine

| Dscription | Specification |

|---|---|

| Welding Method | SAW 2 Poles – 2 Heads |

| Current Range | DC 300~1,500 A / DC 300~1,200 A |

| Welding Wire | Ø 4 ~ 4.8 mm |

| Welding Speed | 0.5~2.0 m/min |

| Carriage Speed | Max. 30 m/min |

| Seam Tracking | Laser Sensor |

| Flux Supply & Recovery | Auto Recycling System |

Longi. Stiffener fit-up machine

| Dscription | Specification |

|---|---|

| Welding Method | FCAW |

| Current Range | Max. 350 A |

| Welding Wire | Ø 1.2~1.6 mm |

| Welding Speed | 100~800 mm/min |

| Carriage Speed | Max. 30 m/min |

| Seam Tracking | Mechanical Guide Roller |

40Poles Stiffener welding machine

| Dscription | Specification |

|---|---|

| Welding Method | FCAW Twin Tandem (5~10 Heads) |

| Current Range | Max. 600 A |

| Welding Wire | Ø 1.2 ~ 1.6 mm |

| Welding Speed | 0.1 ~ 1.5 m/min |

| Traveling Speed | Max. 30 m/min |

| Return Speed | Max. 10 m/min |

| Seam Tracking | Mechanical Guide Roller |

| Welding Database | Memory & Playback |

Robot welding machine

| Dscription | Specification |

|---|---|

| Welding Method | FCAW 1 Pole – 12 Heads |

| Current Range | Max. 600 A |

| Welding Wire | Ø 1.2~1.6 mm |

| Welding Speed | 0.1~0.5 m/min |

| Traveling Speed | Max. 10 m/min |

| Seam Tracking | Touch Sensor, Arc Sensor |

| Robot Type | 5 Axies Articulated |

| Programming Type | Off-line |

| Program Download | LAN |

| Work Division | Cell Controller |

B.L.T line

-

Dscription

- Edge Rounding Machine

- Fit-up Stage

- Main Welding Stage

- Repair Welding Stage

- Shot & Painting Stage

- Straightening Stage

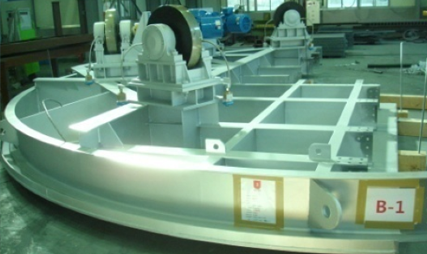

Submarine production line

-

Dscription

- Web Ring Fit-up & Welding

- Flange Butt Fit-up & Welding

- Web Ring Fit-up & Welding

- Web Ring+Flange Ring Welding

- Shell+Frame Fit-up

- Shell Plate+Shell Plate Welding

- Ring Frame+Shell Plate Welding

- Unit+Unit Fit-up & Welding

- Milling Machine

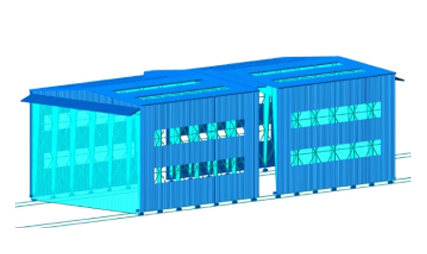

Steel structure fabrication system

H-beam fabrication line

Features

- Gas Cutting System

- In-Feeding Conveyor & Centering Device

- Auto Fit-up & Tack Welding Machine

- Turning Device

- Lifting Device

- Main Welding Machine

- Turning Device

- Straightening Machine

Pipe & Vessel welding line

Auto Orbital GMAW system (2Poles)

-

Features

- Self-diagnosis for System Error & Hardware Connection Error

- Compact & Light Weight

- Smart Remote Display

- Automatic Arc On/Off Control

- Process Monitoring

- High Welding Speed

- Accurate Arc Control

- Pulse or Conventional MIG Welding

-

Dscription Specification Traveling Speed Max. 3.5 m/min Weaving Speed Max. 3.0 m/min Weaving Stroke 50 mm Height Stroke 50 mm Position Resolution 50 mm Min. Pipe Diameter 50 mm

Pipe in/outside welding system

-

Features

- 1) Inner longitudinal Welding System for Steel Pipe (3 Poles)

- 2) Exterior Longitudinal Welding System for Steel Pipe (5 Poles)

- 3) Secondary Material Transport Car

- 4) Secondary Material Transport Conveyor

-

Features

- 1) Standard Specification of Material : Ø44”× 25.4mmt ×12,200mm

- 2) Productivity

- Inner Welding: 3pcs/hr, 1M/C (on the basis of arc rate 70% and operating rate 100%)

- Exterior Welding: 5pcs/hr, 1M/C (on the basis of arc rate 70% and operating rate 100%)

- 3) Product Material: API 5L X42 ~ API 5L X80 (included mild steels)

- 4) Product Shape and Range: Circular Pipe, Ø16~60”, 6~40mmt

- 5) Product Length: 6,000~12,000mm

Iron manufacturing equipment

Coil car, Tilting ladle transfer car

Turn table, beam

Profile cutting line

Transportation equipment

Crane

Tramsfre car

Movable shelter

Portable Heat Exchanger Purification System

-

Features

- 나노-마이크로 버블 발생기

- 오존 발생기

- 초음파 발생기

- high pressure cleaning

Asphalt Product Mixing & Packing System

-

Features

- productivity : 5ton/h

- storage bin : 1ton

- power consumption : 5kW

- overall dimension : L6m×W3m×H2m

Welding Gantry Robot System

Press Line

-

Features

- 차체 프레스 공정 로봇 자동화

Package Line

-

Features

- 포장라인 로봇 자동화

6Speed TM Case & CVT Housing Assembly Line

Features

- TM CASE & CVT HOUSING 자동 조립라인

| C/T | 20HR | 비고 |

|---|---|---|

| 58CH/台 | 1,241台/日 |

Hub Carrier Assy Assembly Line

Features

- TM CASE & CVT HOUSING 자동 조립라인

| C/T | 20HR | 비고 |

|---|---|---|

| 72CH/台 | 1,000台/日 | 반자동 |

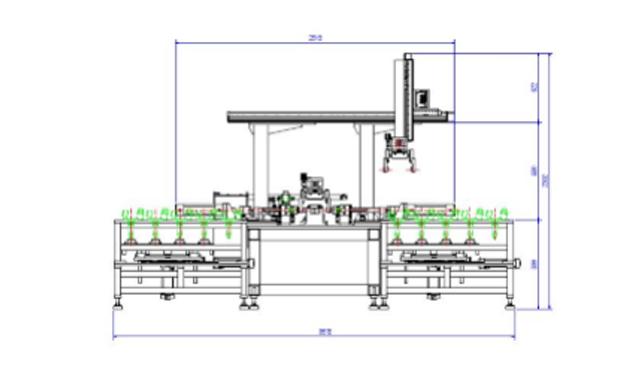

Γ-ENG Ladder Frame Assembly M/C

Features

- Γ-Eng Ladder frame plug bolt (록타이트type) 및 무두 bolt 조립기

| C/T | 20HR | 비고 |

|---|---|---|

| 54CH/台 | 1,334台/日 | 서보 너트런너 사용 (GIKEN社) |

Servonutrunner(2axis)

Features

- RR CARRIER AXLE ASSEMBLY F/NUT 조립기

| C/T | 20HR | 비고 |

|---|---|---|

| 50CH/台 | 1,440台/日 | 서보 너트런너 사용 (GIKEN社) |

Knuckle Bush Pressing machine

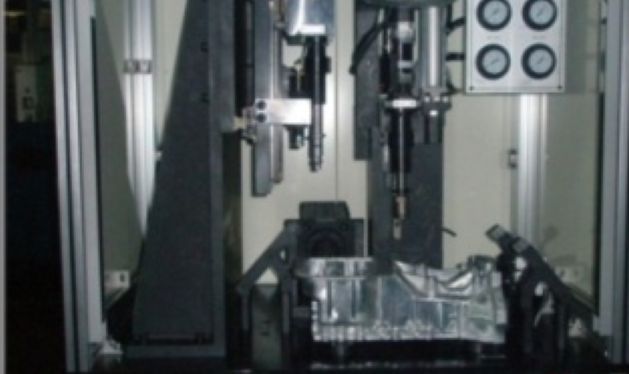

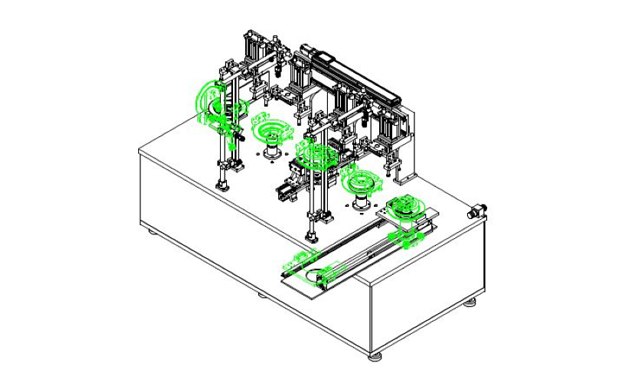

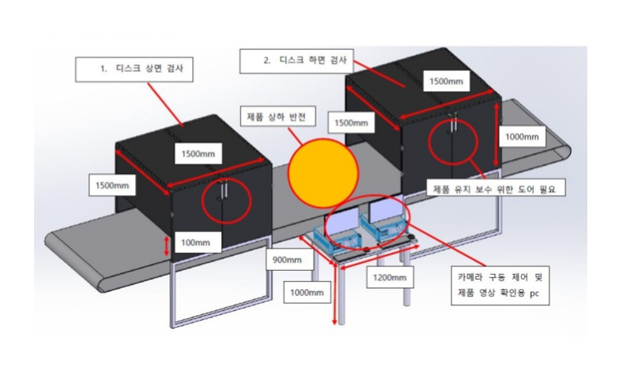

Disc Vision Inspection M/C

Hub Tap Inspection and location Vision Inspection M/C

-

Features

- 비젼 카메라(7대) 활용,DISC 결함 체크